Just show grand | presence and oil 2022 China refrigeration exhibition

Posted time:2022-08-11 View:405From August 1 to 3, 2022, "The 33rd International Refrigeration, Air Conditioning, Heating, Ventilation and Food Refrigeration Processing Exhibition" (hereinafter referred to as "China Refrigeration Exhibition") will be held in Chongqing Expo Center. The exhibition is co-sponsored by Beijing Branch of China Council for the Promotion of International Trade, China Refrigeration Society and China Refrigeration and Air Conditioning Industry Association, organized by Beijing International Exhibition Center Co., LTD., and co-organized by Chongqing Refrigeration Society. With the theme of "Focus on Innovation, Quality and low-carbon health", China Refrigeration Exhibition has set up a total of 8 pavilions, with a total exhibition area of nearly 80,000 square meters, and more than 600 exhibitors have come to the exhibition.

As the industry's leading benchmark and grade frozen oil enterprise, Kanghe Petroleum in this exhibition in a comprehensive display of the company's full range of products, at the same time with sincere service to bring more high-quality solutions for customers, with products and actions to interpret the high-end quality. With a brand new image of Ganghe, Ganghe Petroleum appeared in this refrigeration exhibition. Simple and elegant booth design, well-arranged product display, from design to pattern, from image to quality, conveying the strength and confidence of Ganghe SynCold brand to our customers.

Ganghe Petroleum with excellent product quality, perfect solutions, strong supply strength to attract a lot of visitors to visit and negotiate, the scene of the crowd, to add a beautiful pen for the booth.

International standard, authoritative certification

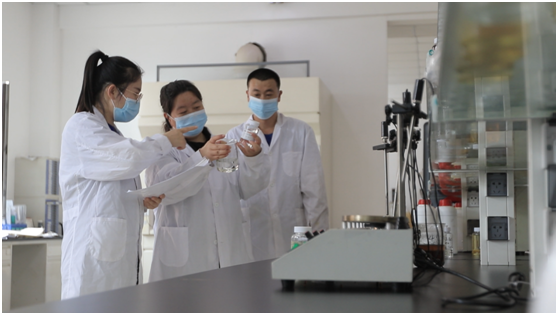

Kanghe Petroleum Research and development Center is equipped with advanced laboratory analysis equipment and testing means, and a sound service and technical support system. It has passed the ISO9001 quality management system certification and ISO14001 environmental management system certification. ISO45001 Occupational health and safety system certification, REACH EU chemical management system certification, RoHS EU environmental protection certification, NSF international food safety certification and other international authoritative certification. At present, we have more than 70 sets of testing equipment, which has realized the step-by-step verification process from sample research and development to pilot production, pilot scale up and quantitative production, ensuring the quality and stability of mass production transformation.

The categories are complete and widely used

The core business of Kanghe Petroleum refrigeration is mainly divided into ten series (DRA H, DRG, GS, SH, PAO, RLD, RL, RLT, AB, PAG). The products cover nearly 34 brands and various specifications, widely used in nuclear power, aerospace, ship and ocean engineering, medical, air conditioning and refrigerator refrigeration, cold storage refrigeration, equipment manufacturing, automobile industry, electronic information and other military and civil industries.

Committed to innovation, optimization lubrication

Ganghe Petroleum focuses on innovation to make up for the domestic gap, and insists on driving the enterprise forward with technological innovation. The company has set up a scientific research team led by industry experts based on the accumulated achievements of innovative research and development technology and equipment in recent years, combined with the concept of intelligent manufacturing. Centering on the core goal of "optimization of lubrication", the cross-promotion and integration from compound structure analysis and improvement, synthetic chemical process design, refrigeration lubricant product formulation and blending process, etc., ensures the practicability and foresight of refrigeration lubricant products.

Craftsman spirit to build industrial ecology

Ganghe Petroleum advocates the craftsman spirit, advocating the craftsman spirit of meticulousness and excellence into every link to make products. At present, Ganghe Petroleum has 10 sets of stainless steel high-pressure sealed reactor with larger single volume in China, with special sewage and waste gas treatment equipment, which can handle acidic and alkaline wastewater, waste gas, and hazardous chemicals storage and transportation site management is perfect. The operating temperature range of production is -30℃-300℃, with atmospheric and vacuum distillation, alkali washing, solvent recovery and other units. With the whole process of industrial production of synthetic ester products independent production, to ensure the stability and reliability of product quality. The multi-stage filtration system ensures the cleanliness of the filtration export products. NAS3, the whole process is protected by nitrogen, which can effectively guarantee the product quality and ensure the safety of product storage and transportation.

Committed to innovation and optimization of lubrication, environmental protection and energy saving service refrigeration ", to improve the international competitiveness of China's refrigeration lubricant as its own duty, to build into an international technology innovative enterprise as the goal. Today, Ganghe Petroleum is stepping on the technological revolution of The Times, in the continuous breakthrough and innovation, stride forward towards the future.